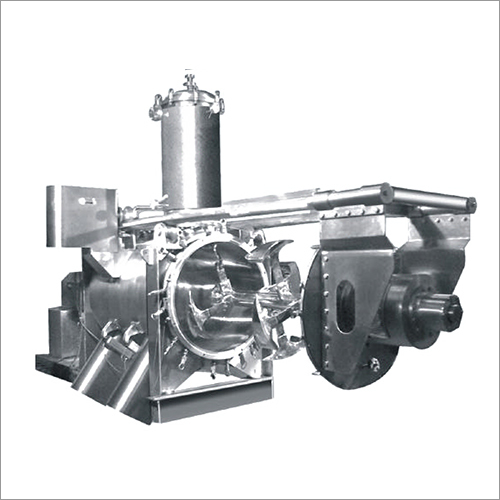

Nauta Cone Screw Mixer

Nauta Cone Screw Mixer Specification

- Heat Source

- External jacket heating (optional)

- Temperature

- Ambient to 200C (max, depends on process)

- Power Consumption

- Approx. 6 kWh (standard model)

- Fuel Type

- Electric or steam (for jacketed heating)

- Power

- 5 - 15 kW (varies by capacity)

- Usage

- industrial

- Material

- Stainless Steel

- Voltage

- 415V AC, 3 Phase, 50Hz

- Product Type

- Nauta Cone Screw Mixer

- Technology

- Nauta Conical Screw Mixing Technology

- Dimension (L*W*H)

- Customized as per capacity

- Color

- Sliver

- Drive Type

- Gearbox driven motors

- Discharge Valve

- Bottom discharge with either manual or automated operation

- Control Panel

- Included (basic or PLC optional)

- Mixing Time

- 15-45 minutes (depending on material)

- Installation Type

- Vertical Free Standing

- Surface Finish

- Mirror/Matte as per requirement

- Mixing Capacity

- 500 to 10,000 Liters (custom options available)

- Speed

- Screw: 10-40 RPM, Arm: 1-5 RPM

- Suitable Materials

- Powders, granules, pastes, viscous materials

About Nauta Cone Screw Mixer

Product details

- Cone Height : 42 to 146 (in Inches)

- Outer Diameter : 44 to 112 (in inches)

- Application : Industrial

- Material : Stainless Steel

- Brand : Bifriends Engineering

- Capacity : 3.3 to 150 Cu. Ft.

Efficient Mixing Technology

Harnessing advanced Nauta Conical Screw Mixing Technology, the mixer ensures thorough and uniform blending of disparate materials, from light powders to heavy pastes and viscous substances. The vertical, free-standing design enhances operational stability, while the customizable drive speeds allow optimal mixing for a range of industrial requirements.

Customizable for Diverse Processes

Clients can tailor nearly every aspect, from the mixing capacity and surface finish to control options. The mixer includes a basic control panel, with an optional PLC system for more intricate automation needs. Discharge valves and heating jackets are selectable, supporting process-specific configurations.

Durability and Safety

Engineered with high-grade stainless steel and offered in both matte and mirror finishes, this mixer provides excellent resistance to corrosion and wear. It is capable of withstanding ambient to high process temperatures, with robust insulation for heated applications. Safety features and compliance with industry standards ensure reliable, long-term operation.

FAQs of Nauta Cone Screw Mixer:

Q: How does the Nauta Cone Screw Mixer operate for different types of materials?

A: The mixer uses a conical screw technology that can handle powders, granules, pastes, and even viscous materials. Adjustable screw and arm speeds enable process flexibility, ensuring optimal mixing times and uniformity regardless of material consistency.Q: What is the usual process for installing the Nauta Cone Screw Mixer?

A: Installation is straightforward since the unit is designed as a vertical, free-standing system. Dimensions are customized according to capacity, and our technical team provides full support from delivery through commissioning at your industrial site.Q: When is external jacket heating recommended?

A: External jacket heating is optional and advised when your mixing process requires temperature control, such as for pasteurizing, drying, or heating materials up to 200C. You can choose between electric or steam-powered jackets based on your facilitys infrastructure.Q: Where is the discharge point located and how is it operated?

A: The mixer is equipped with a bottom discharge valve, available in manual or automated versions. This design enables quick and efficient unloading of processed materials, minimizing residual content and facilitating easy cleaning.Q: What type of control panel is included, and can it be upgraded?

A: A standard basic control panel is provided, which can be upgraded to advanced PLC controls for automated and programmable mixing cycles, catering to complex process demands.Q: How can operators benefit from using this mixer in industrial processes?

A: Operators gain efficiency through reduced mixing times, reliable process control, and flexible configuration. The systems robust construction and temperature range support various manufacturing applications, leading to consistent product quality and improved productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dryer Category

Cantilever Roto cone Vaccum Dryer

Minimum Order Quantity : 1 Unit

Usage : Industrial

Product Type : Cantilever Rotocone Vaccum Dryer

Color : Silver

Material : Stainless Steel

Warranty : 1 Year

Spherical dryer

Minimum Order Quantity : 1 Unit

Usage : Industrial

Product Type : Spherical dryer

Color : Silver

Material : Stainless Steel

Warranty : 1 Year

Agitated Nutsche Filter Dryer

Minimum Order Quantity : 1 Unit

Usage : Industrial

Product Type : Agitated Nutsche Filter Dryer

Color : Silver

Material : Stainless Steel

Warranty : 1 Year

Retractable Plough Shear Mixer Dryer

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Retractable Plough Shear Mixer Dryer

Color : Silver

Material : Stainless Steel

Warranty : 1 Year

|

BEW ENGINEERING LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry