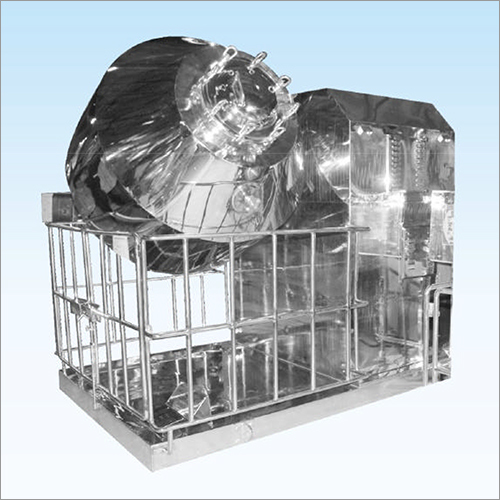

Rotary Vacuum Paddle Dryer

MOQ : 1 , , Piece

Rotary Vacuum Paddle Dryer Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Voltage

- 220-415 Volt (v)

- Product Type

- Rotary Vacuum Paddle Dryer

- Color

- Silver

- Warranty

- 1 Year

Rotary Vacuum Paddle Dryer Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 3 Pieces Per Month

- Delivery Time

- 2-3 Week

About Rotary Vacuum Paddle Dryer

Rotary Vacuum Paddle Dryer is a complete drying system designed to obtain dry powder from wet cake or solution. It is used in industrial applications where drying is generally carried out in a batch process under vacuum conditions. This product is heated through direct contact for improving its performance. It has got high build quality and bespoke design, therefore, we are seeing a huge demand for the Rotary Vacuum Paddle Dryer in the marketplace. Our customers can get this product delivered to their door-step within the stipulated time frame.

Rotary Vacuum Paddle Dryer Specifications:

- Material for Constructions: Stainless steel

- Power Source: Electric

- Automatic Grade: Automatic

- Capacity: 500 Litres

Robust Industrial Drying Performance

Engineered for rigorous industrial applications, the Rotary Vacuum Paddle Dryer offers uniform and gentle drying for heat-sensitive substances. The stainless steel construction ensures longevity and low maintenance. Operating under vacuum improves energy efficiency, reduces drying time, and helps preserve product quality, making it highly suitable for chemical, pharmaceutical, and food processing industries.

Versatile Power Compatibility

Adaptable to varied electrical environments, this dryer functions smoothly across a voltage spectrum from 220 to 415 volts. Its flexible design makes it ideal for industrial facilities in different regions. Easy integration into existing process setups reduces hassle and optimizes productivity.

FAQs of Rotary Vacuum Paddle Dryer:

Q: How does the Rotary Vacuum Paddle Dryer work in industrial applications?

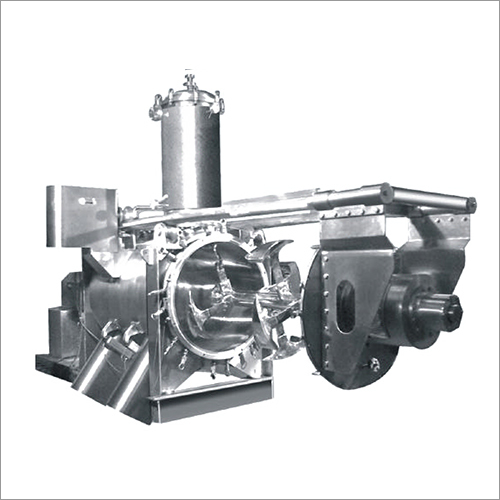

A: The Rotary Vacuum Paddle Dryer uses rotating paddles inside a vacuum-sealed chamber to efficiently agitate and dry materials by lowering drying temperatures. This process ensures even and gentle drying, suitable for sensitive compounds in industrial settings.Q: What materials and colors are available for this Rotary Vacuum Paddle Dryer?

A: This dryer is constructed from premium stainless steel, providing excellent corrosion resistance. It is available in a polished silver color, contributing to both durability and a professional appearance.Q: When is maintenance required for the Rotary Vacuum Paddle Dryer?

A: Routine maintenance is typically recommended every six months, although the frequency may vary depending on the nature of the processed materials and operating conditions. The stainless steel build reduces corrosion risk and maintenance burdens.Q: Where is this dryer manufactured and to which markets do you export?

A: The dryer is manufactured in India and supplied as an exporter, manufacturer, service provider, and supplier. Our products reach clients both domestically and internationally across various industries.Q: What is the process for installing and commissioning the Rotary Vacuum Paddle Dryer?

A: Our experts provide complete installation and commissioning services, ensuring seamless integration with your existing systems. Support includes on-site setup, testing, and operational training for facility staff.Q: How is the dryer used, and what are its primary benefits?

A: The Rotary Vacuum Paddle Dryer is used to dry chemical, pharmaceutical, and food substances that require controlled, low-temperature environments. Key benefits include efficient drying, minimal contamination risk, and enhanced product quality.Q: What warranty coverage is included with this product?

A: We provide a 1-year warranty covering manufacturing defects and operational issues. Our service team offers prompt support and repair services within the warranty period for your peace of mind.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Dryer Category

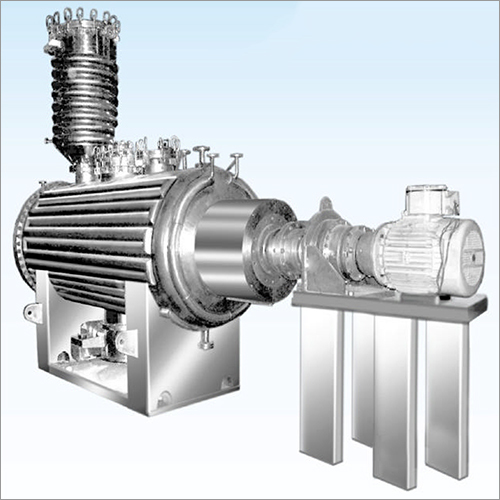

Cantilever Vacuum Dryer

Minimum Order Quantity : 1 , , Piece

Color : Silver

Material : Other, Stainless Steel 316 / 304

Voltage : 380415 Volt (v)

Agitated Pan Dryer

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Stainless Steel

Product Type : Agitated Pan Dryer

Warranty : 1 Year

Voltage : 220440 Volt (v)

Nutsche Filter Dryer

Minimum Order Quantity : 1 , , Piece

Color : Silver

Material : Stainless Steel

Product Type : Nutsche Filter Dryer

Warranty : 1 Year

Voltage : 220 Volt (v)

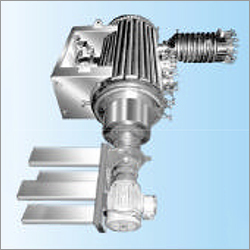

Retractable Plough Shear Mixer Dryer

Minimum Order Quantity : 1 Piece

Color : Silver

Material : Stainless Steel

Product Type : Retractable Plough Shear Mixer Dryer

Warranty : 1 Year

Voltage : 220415 Volt (v)

|

BEW ENGINEERING LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry