Cantilever Vacuum Dryer

Cantilever Vacuum Dryer Specification

- Temperature

- Up to 150C Celsius (oC)

- Power Consumption

- Approx. 7.5 kW/hr Kilowatt (kW)

- Heat Source

- Steam / Hot Water / Thermal Oil

- Fuel Type

- Electric / Oil / Gas

- Material

- Stainless Steel 316 / 304

- Voltage

- 380415 Volt (v)

- Technology

- Cantilever Vacuum Drying

- Color

- Silver

Cantilever Vacuum Dryer Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 3 Pieces Per Month

- Delivery Time

- 2-3 Week

About Cantilever Vacuum Dryer

Innovative Cantilever Agitator Design

The Cantilever Vacuum Dryer features a unique agitator without bottom support, which minimizes mechanical wear and optimizes the mixing and drying of sensitive products. This design enhances the efficiency of heat transfer, ensures uniform drying, and prevents contamination, making it ideally suitable for high-purity requirements in pharmaceutical and chemical processing.

Comprehensive Control and Automation

Equipped with a PLC-based control panel and optional touchscreen interface, this dryer offers precise regulation of temperature, pressure, and agitation parameters. The automation ensures consistent batch quality, easy monitoring, and adaptable process control to meet diverse product specifications. Seamless integration into existing systems is straightforward, resulting in a streamlined production workflow.

FAQs of Cantilever Vacuum Dryer:

Q: How does the Cantilever Vacuum Dryer operate?

A: The dryer works by creating a vacuum inside the chamber, reducing the boiling point of moisture for rapid drying at temperatures up to 150C. The cantilever agitator stirs the product, ensuring consistent drying without dead spots or material buildup. A heating medium such as steam, hot water, or thermal oil is circulated through the jacket, and moisture is efficiently evacuated through an oil-sealed rotary or water ring vacuum pump.Q: What are the main benefits of using this dryer in pharmaceutical or chemical industries?

A: This dryer minimizes contamination risks thanks to its cantilever design and mirror or electro-polished finishes. Its ability to efficiently dry sensitive, heat-labile materials while maintaining purity, combined with automated controls and easy cleaning (CIP/SIP), makes it ideal for regulatory compliance in pharmaceutical and high-value chemical production.Q: When is CIP/SIP cleaning recommended for this equipment?

A: CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems are recommended after each batch or between product changes to eliminate contamination and ensure product safety, particularly in pharmaceutical and food industries. The integrated provision for CIP/SIP in this vacuum dryer streamlines maintenance and reduces downtime.Q: Where can this Cantilever Vacuum Dryer be installed?

A: Designed for horizontal cantilevered installation, its compact, customizable footprint allows integration into new or existing facilities across pharmaceutical, chemical, food, and allied industries. Dimensions can be tailored to site-specific requirements to optimize space and process flow.Q: What applications and products are suited for this dryer?

A: The Cantilever Vacuum Dryer is perfect for drying sensitive, hygroscopic, or heat-sensitive powders, granules, pastes, and wet cake in the pharmaceutical, chemical, and food sectors. It is especially beneficial for products requiring strict control over contamination and temperature uniformity.Q: How is product discharged and what are the options available?

A: Product discharge from the dryer is handled through a bottom outlet, with options for manual or automated operation. Automated product discharge can enhance safety, reduce labor costs, and increase throughput, particularly for large batch processing.Q: What types of gaskets and materials of construction are available?

A: The vacuum dryer is constructed from Stainless Steel 316 or 304, ensuring corrosion resistance and hygiene. Gasket materials can be selected based on process needsSilicone, Viton, or PTFEproviding compatibility with a wide range of chemical and pharmaceutical products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dryer Category

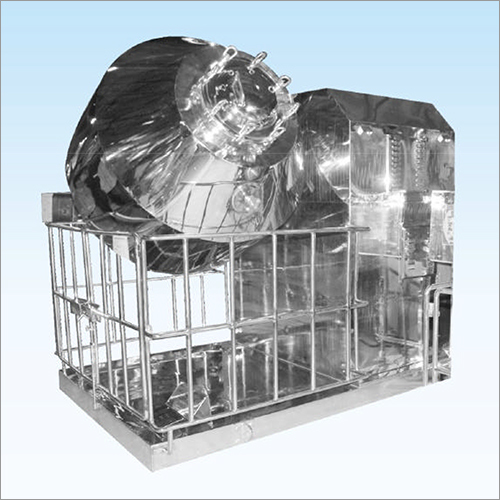

Spherical Dryer

Minimum Order Quantity : 1 , , Piece

Usage : Industrial

Color : Silver

Product Type : Spherical Dryer

Material : Stainless Steel

Warranty : 1 Year

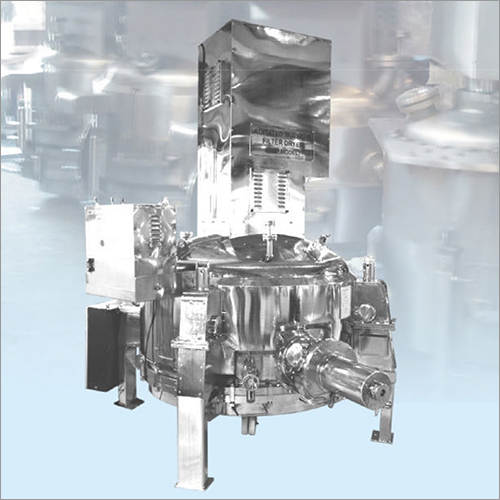

Nutsche Filter Dryer

Minimum Order Quantity : 1 , , Piece

Usage : Construction

Color : Silver

Product Type : Nutsche Filter Dryer

Material : Stainless Steel

Warranty : 1 Year

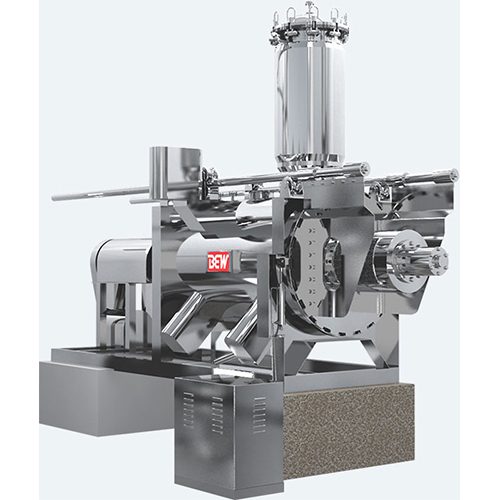

Plough Shear Mixer Dryer

Minimum Order Quantity : 1 Unit

Usage : Industrial

Color : Silver

Product Type : Plough Shear Mixer Dryer

Material : Stainless Steel

Warranty : 1 Year

Agitated Pressure Nutsche Filter Dryer

Minimum Order Quantity : 1 Piece

Usage : Industrial

Color : Silver

Product Type : Agitated Pressure Nutsche Filter Dryer

Material : Stainless Steel

Warranty : 1 Year

|

BEW ENGINEERING LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry